Resolving Flatness in Tooling

Emotional Intelligence in Quality

February 18, 2013

Evaluating Vendor Dimensional Differences

May 23, 2013Resolving Flatness in Tooling

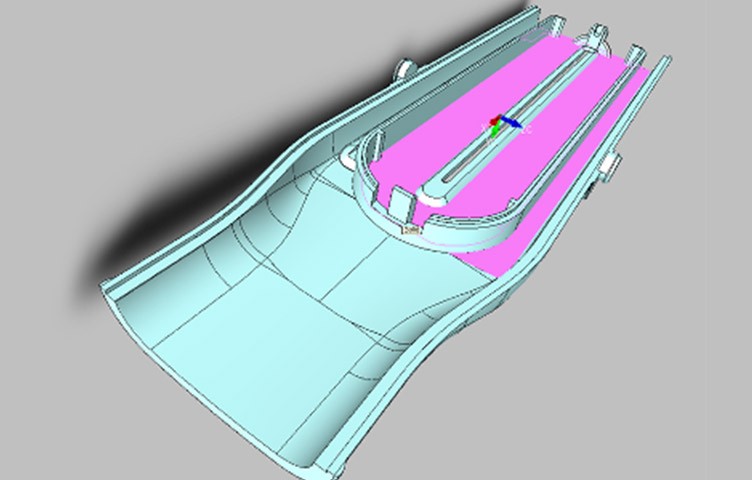

When molding plastics and metals, flatness often requires special attention for steady control. After molding process parameters have been stabilized, the tool may need to be modified to compensate for consistent warp or sinks in the part. Modifying the tool can be an iterative process, requiring many attempts until flatness of the part can be steadily maintained. With precision scanning, the number of revisions can be reduced. Scanning the manufactured part allows for a NURBS surface fileto be created that accurately represents the amount and location of the out-of-flat condition. This surface file can then be used to create an electrode to re-burn the tool and ‘correct’ the finished part back to a flat condition.

First-hand experience in tooling and operations is critical to providing a scanning solution that works.

That is why QC’s Engineering team can provide a high-value solution for your problem at hand.

– David

Read more articles like this one in our article archive.