Scanning and CAD Modeling

Medical Devices.

Precision. On Time.

QC Engineering can rapidly scan and verify medical components throughout the development of your device – often turning results in 24 hours. Our Engineering team has extensive experience in the scanning, inspecting and CAD modeling of medical devices so your geometry will be ready for tooling development. Scanning applications include mating component analyses, surface area analyses, and full CAD model development. Our capabilities are structured to assist you from precision device development into full production. Your project will be personalized - managed by a highly skilled individual with whom you will have a direct line of communication.

Scanning and CAD Modeling

Medical Devices.

Precision. On Time.

QC Engineering can rapidly scan and verify medical components throughout the development of your device – often turning results in 24 hours. Our Engineering team has extensive experience in the scanning, inspecting and CAD modeling of medical devices so your geometry will be ready for tooling development.

Providing Capability & Capacity

Scanning applications include mating component analyses, surface area analyses, and full CAD model development. Our capabilities are structured to assist you from precision device development into full production.

With Direct Communication

Your project will be personalized - managed by a highly skilled individual with whom you will have a direct line of communication.

Tell us about your project! Call 952-895-1150. 8am-5pm CST

- Story-Worthy Service

- Equipment, Capabilities

- Accreditation, Certifications

- Sample Outputs, Files

- Scanning vs CMM Inspection

Story-Worthy Engineering Services

Built for responsiveness.

QC Engineering strives to provide services worth telling others about. We've structured our entire operation to be responsive to your needs – from precision equipment to be used for medical devices, to IT systems built for optimum communications; we strive in every way to provide story-worthy service.

To take you to the next step.

When you begin a project with us, we'll want to know your stated and unstated project needs. We value making and keeping aggressive commitments to help you get to the next step in your project. With equipment and skills specifically developed for precision components, we’ll find the best approach to completing your project. You’ll know the accuracy of the CAD model we provide by attending a live on-line review of the CAD geometry compared to the scanned part.

Equipment, Capabilities.

Scanning Platforms

- CMM Laser Scanners

- Chromatic White Light Scanning Interferometry

- Confocal Micro Laser Scanner

- Portable CMMs with Laser Scanning

- CT Scanning (internal geometries)

Software Platforms

- Geomagic

- Polyworks

- Rapidform

- SolidWorks

- Pro-E, Creo

- AutoDesk Inventor

- Rhinoceros

Support Capabilities

- Robust Inventory Control System

- Class 10,000 Clean Room Inspection

- Polishing Wheel

- Cutoff Machine

- Parts Cleaning Station

For specific inquiries about equipment, software platforms and scanning capability, send us a message or call 952-895-1150.

Qualifications, Accreditations, and Certifications.

Plastics Technology

All CAD Specialists have completed Designing Plastic Parts for Injection Molding studies.

ITAR Registered

ASQ Certifications

All inspectors are certified to one or more of the following:

- CQI (Certified Quality Inspector)

- CMI (Certified Mechanical Inspector)

- CQT (Certified Quality Technician)

- CQE (Certified Quality Engineer)

- CQM (Certified Quality Manager)

- CQA (Certified Quality Auditor)

- Duns Number:19-993-4829

- NAICS: 541380 (Mech. Testing Lab or Services)

- Cage Code: 0GB04

- SIC Code: 8734

Something missing? Send us a message or call 952-895-1150 with special considerations.

Scanning Outputs

Point Cloud

- Raw 3D Scan Data (.txt, .asc)

Generated by all 3D scanning technologies, raw geometric data is collected as a point cloud. This is the first step in every project.

Polygons

- Raw 3D Scan Data with a polygonal wrap (.stl)

Neutral file primarily used by the 3D printing industry.

Analysis

- 2D Visual Report (.pdf)

- 3D Interactive Report (.pwzip)

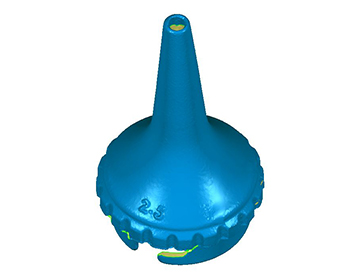

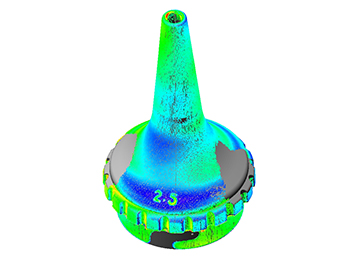

Point cloud data is overlaid to an existing CAD model or scan data of another part to show deviation. Used for rapid design verification, tooling validation, and first article inspection.

Referred to as a Deviation Analysis, Comparative Analysis, Computer Aided Inspection (CAI) or Verification (CAV), or Color Map. Reports can also be manipulated to show specific dimensional call outs or FAIs. We call this a "CAV Plus".

Modeling Outputs

Native Parametric Formats

Models developed in your native CAD platform. Constructed with a fully functional design tree, robust models are built for ease of editing.

NURBS File Format

Best for modeling organic shapes that do not need to be edited. Surface or solid file output (.igs, .stp)

All Reverse Engineering and Modeling project customers receive a Live Model Review at project completion.

Need a closer look?

Download fully featured sample files in all of these formats from our download center.

When you may need dimensional inspection vs 3D scanning.

Is your project in its final validation (first article) stage?

A 3D scan may be an acceptable final validation for your project. However, if you need complete dimensional results as specified by the part print, a full FAI using a CMM or other inspection tools may be a better solution.

Do you need accuracy less than 8 microns?

When your tolerances are in the 2-10 micron range, a touch probe or vision CMM is a better solution than 3D scanning. Chromatic white light scanning and confocal micro-laser scanning will produce tighter accuracies, but are limited to relatively flat surfaces, measuring micro-topography.

Does your inspection involve a large number of dimensions?

Measuring multiple features can be done with both a traditional CMM and by extracting the data from a 3D scan. However, it is generally more efficient to extract a few dimensions from a 3D scan than several hundred. As a guide, 20 (or fewer) dimensions on 1 or 2 parts is a good number for 3D scanning. As the dimensions and number of pieces increase, programming and inspecting with a CMM is more cost effective.

Helping you find the best solution.

QC Engineering is dedicated to helping you solve your quality and design challenges. In these situations, we work with QC Inspection to create solutions that are comprehensive, cost-effective, and appropriate to achieve your goals.

Explore Dimensional InspectionSend us a message, or call us 952-895-1150, and let us guide you to the right solution.

Story-Worthy Engineering Services

Built for responsiveness.

QC Engineering strives to provide services worth telling others about. We've structured our entire operation to be responsive to your needs – from precision equipment to be used for medical devices, to IT systems built for optimum communications; we strive in every way to provide story-worthy service.

To take you to the next step.

When you begin a project with us, we'll want to know your stated and unstated project needs. We value making and keeping aggressive commitments to help you get to the next step in your project. With equipment and skills specifically developed for precision components, we’ll find the best approach to completing your project. You’ll know the accuracy of the CAD model we provide by attending a live on-line review of the CAD geometry compared to the scanned part.

Equipment, Capabilities.

Scanning Platforms

- CMM Laser Scanners

- Chromatic White Light Scanning Interferometry

- Confocal Micro Laser Scanner

- Portable CMMs with Laser Scanning

- CT Scanning (internal geometries)

Software Platforms

- Geomagic

- Polyworks

- Rapidform

- SolidWorks

- Pro-E, Creo

- AutoDesk Inventor

- Rhinoceros

Support Capabilities

- Robust Inventory Control System

- Class 10,000 Clean Room Inspection

- Polishing Wheel

- Cutoff Machine

- Parts Cleaning Station

For specific inquiries about equipment, software platforms and scanning capability, send us a message or call 952-895-1150.

Qualifications, Accreditations, and Certifications.

Plastics Technology

All CAD Specialists have completed Designing Plastic Parts for Injection Molding studies.

ITAR Registered

ASQ Certifications

All inspectors are certified to one or more of the following:

- CQI (Certified Quality Inspector)

- CMI (Certified Mechanical Inspector)

- CQT (Certified Quality Technician)

- CQE (Certified Quality Engineer)

- CQM (Certified Quality Manager)

- CQA (Certified Quality Auditor)

- Duns Number:19-993-4829

- NAICS: 541380 (Mech. Testing Lab or Services)

- Cage Code: 0GB04

- SIC Code: 8734

Scanning Outputs

Point Cloud

- Raw 3D Scan Data (.txt, .asc)

Generated by all 3D scanning technologies, raw geometric data is collected as a point cloud. This is the first step in every project.

Polygons

- Raw 3D Scan Data with a polygonal wrap (.stl)

Neutral file primarily used by the 3D printing industry.

Analysis

- 2D Visual Report (.pdf)

- 3D Interactive Report (.pwzip)

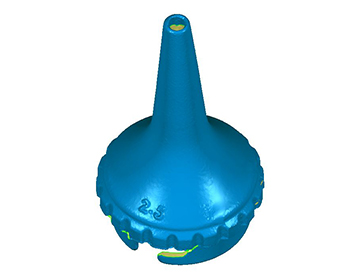

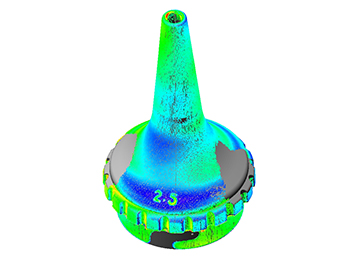

Point cloud data is overlaid to an existing CAD model or scan data of another part to show deviation. Used for rapid design verification, tooling validation, and first article inspection.

Referred to as a Deviation Analysis, Comparative Analysis, Computer Aided Inspection (CAI) or Verification (CAV), or Color Map. Reports can also be manipulated to show specific dimensional call outs or FAIs. We call this a "CAV Plus".

Modeling Outputs

Native Parametric Formats

Models developed in your native CAD platform. Constructed with a fully functional design tree, robust models are built for ease of editing.

NURBS File Format

Best for modeling organic shapes that do not need to be edited. Surface or solid file output (.igs, .stp)

All Reverse Engineering and Modeling project customers receive a Live Model Review at project completion.

Tell us about your project! Call 952-895-1150. 8am-5pm CST

"Surely use them. Lovely services and people. Thank you so much for your great service and wonderful positive attitudes."

- Mahy A, St. Jude Medical