1

1Scanning

2

2Processing

3

3Alignment

4

4Processing

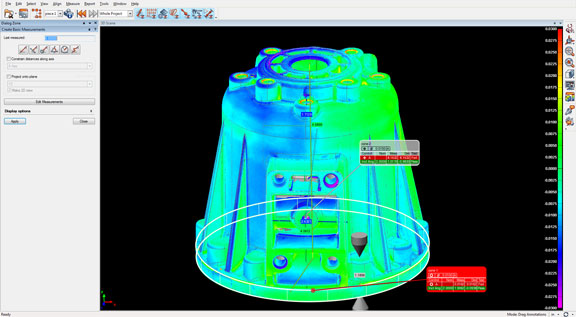

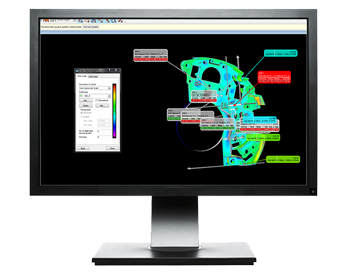

Flexible Delivery. Powerful Reports

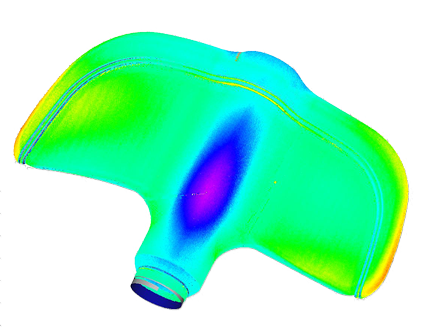

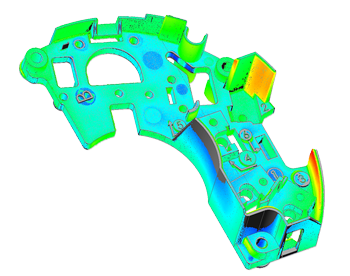

The output of every Deviation Analysis project includes a interactive 3D report, and a powerful viewer app called IMView. The deviation between the base and scan data can be represented in any way that is useful to you - Pass/Fail, color scales with custom range, etc. This viewer/report deliverable provides the ability for you to further interrogate the data and create custom reports in the future. Specific dimensional call outs can be taken from this report and published as a FAI data spreadsheet. This hybrid deliverable is called a CAV Plus.