What can we scan?

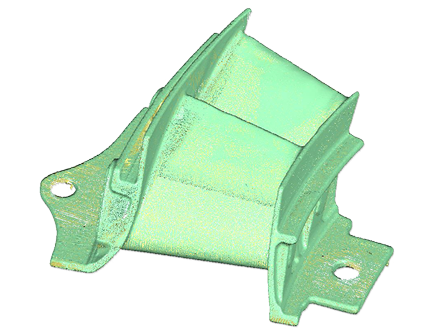

From the face of a penny, to the contours of a fighter jet and everything in between. A variety of scanning technologies are leveraged as needed given constraints of material, size and complexity. See how scanning can be used in your industry.Scanning Platforms

- Red Light Laser

- Blue Light Laser

- White Light

- CMM-Mounted Systems

- Arm-Mounted Portable Systems

- CT Scanning (for internals)

Applications & Outputs

- Deviation Analysis

- Reverse Engineering

- RAW Point Data

- Neutral Files