Evaluating Vendor Dimensional Differences

Resolving Flatness in Tooling

April 3, 2013

Timing in the Hiring Process: Tomorrow is never the same as today.

September 23, 2013Evaluating Vendor Dimensional Differences

Here’s another of the many ways in which laser scanning is being used in the development and validation of precision products…

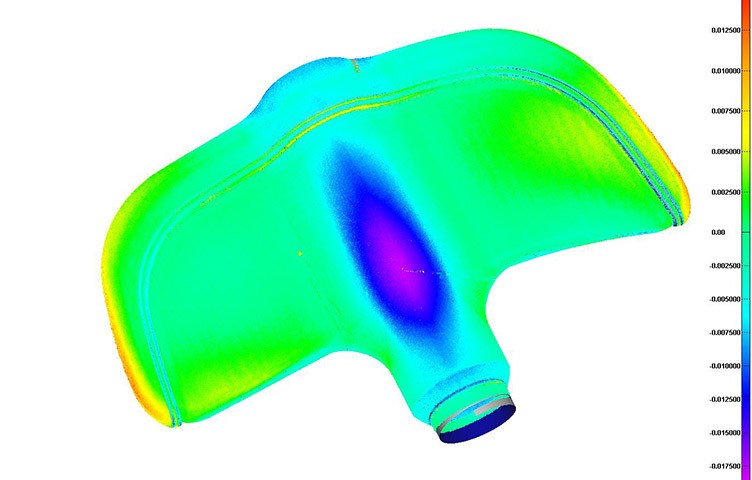

Sometimes the difference in how parts function is best evaluated by overlaying one piece onto another. QC’s Engineering Specialists do this by performing a full 3D scan of both pieces, creating an STL file of one of the point clouds, and generating a comparative analysis (see image below) of the other to the first STL file. The result is a 3D image, exposing the differences between the two parts.

It’s an excellent and proven approach to evaluating performance between vendors or mold cavities – with the goal of improving performance of the product.

Let us know what you need to accomplish and our team will recommend the best solution to help you solve your dimensional challenges.

Call or send us a message, if you have a project you’d like to discuss or if you simply have a question I might help you with.

– David

You can find several similar articles on laser scanning, 3D modeling, reverse engineering on our Article Archive.