Four Ways to Reduce Laser Scanning Costs.

Referral Bonus Increased to $250 with Unlimited Earning Potential!

January 14, 2015

5 Tips for an Outstanding Resume | Webinar.

January 23, 2015Four Ways to Reduce Laser Scanning Costs.

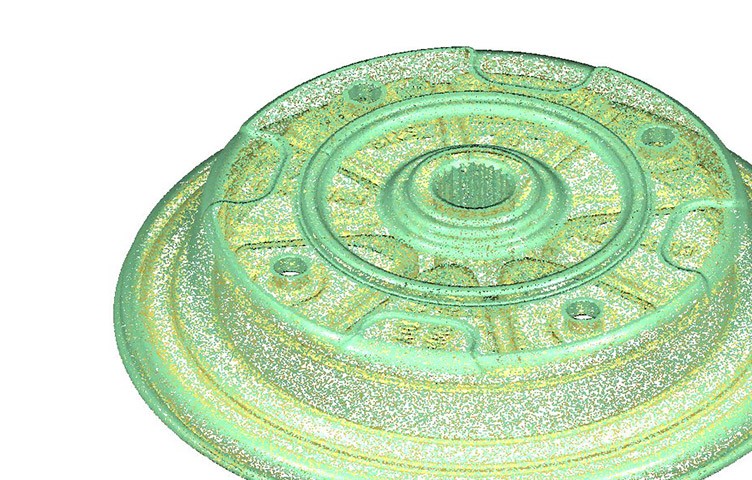

Control Scanning Costs Without Sacrificing Quality and Precision.

Everyone is looking to control costs. You want your budget to stretch as far as it can – of course, without sacrificing performance or quality. That, is the ideal. In the area of laser scanning and inspection, one cost-cutting measure is to settle for a lower-accuracy system. Lower standards are cheap. For precision manufacturers who are interested in quality, that’s not a viable option. Here are 4 ideas focused on controlling scanning and modeling costs while maintaining accuracy and integrity of the results.

1. Limit the number of parts to be scanned.

Designers often want to see variability between parts to determine tolerances for a new product. Tolerances should be developed from the part assembly, performance metrics, and industry standards. Variation from part to part only gives a tiny snapshot of how the manufacturing process performed when the parts were being made. Scan multiple parts when you need averages to produce a “golden model” of the point cloud, or if you want “good” and “bad” results compared, or if you need another valid comparison such as between cavities or between suppliers.

2. Scan only one side.

If only one area of the part is critical to you, don’t spend the money to scan all features. Much more time is involved in producing a 360-degree scan of an object. Scanning a single side is most useful if you have a critical sealing surface or the part is uniform in thickness (such as a precision metal stamping).

3. Use the “least” level of file output that will work for your application.

This advice comes with a word of caution; don’t compromise by purchasing a file you can’t use. With that in mind, the cost of the project increases along a progression of file types, generally in this order: point cloud, STL, comparative analysis, NURBS surface, native parametric, 2D prints. The farther down the line, the more cost that’s involved. Choose the file type that best fits your application.

4. Use a method other than scanning.

If you are looking for detailed measurements from your scan, your least expensive solution may be to apply traditional dimensional inspection using a CMM or other mechanical equipment. Laser scanning and white light scanning have their place, but they may not be your most cost effective approach to achieve your end result.

QC Engineering can partner with you to ensure that your scanning projects are within budget while maintaining accuracy and integrity of the results. Send us a message to learn more or request a quote online.