Process Validation for Injection Molding

We’re still here for you!

February 21, 2014

You Have Six Seconds.

May 15, 2014Process Validation for Injection Molding

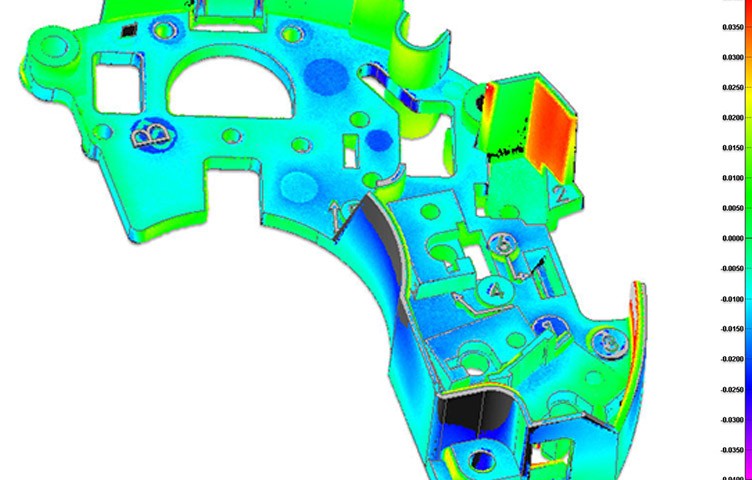

Validating your injection molding process is critical to consistently producing high quality parts that must meet customer specifications. Precision laser scanning can provide a complete understanding of how your part is affected by changes in process parameters. You will be able to analyze profiles and geometry that cannot be fully characterized by CMM measurements.

A typical scan and comparative analysis can be accomplished in less than 48 hours. The cost for 3 average sized parts is usually less than $400.

Precision laser scanning is used to accurately capture 100% of the part geometry. Comparative analysis identifies and quantifies deviations of all profiles and geometry. The point cloud can be analyzed against the 3D model or between parts. Use the comparative analysis to perform a direct comparison of parts between validation runs. It can also be used to capture specific feature dimensions.

Send us a simple quote request or give us a call (952-895-1150) to find out how we can help you streamline and grow your business.