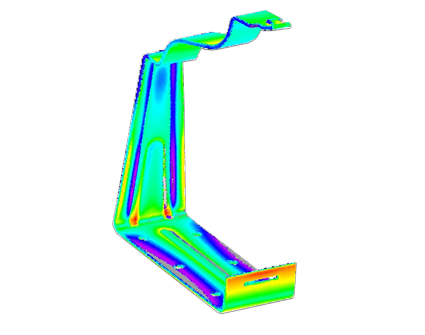

The deliverable of a Deviation Analysis project can also be referred to as a Comparative Analysis, Computer Aided Inspection (CAI), Computer Aided Verification (CAV), or Color Maps. Point cloud data is overlaid to an existing CAD model or scan data of another part to show deviation. Used for rapid design verification, part-to-part comparison, tooling validation, and first article inspection.

952-895-1150 8a-5p Mon-Fri, CST

QC Group, LLC. | Headquarters

5950 Clearwater Drive, Suite 300

Minnetonka, MN 55343

Get Directions | 952-895-1150

Irving, Texas

4100 W Royal Lane, Suite 125

Irving, TX 75063

Get Directions | 972-915-4333

Albuquerque, New Mexico

1451 Innovation Parkway SE, Suite 650

Albuquerque, NM 87123

Get Directions | 505-299-0975

Effective July 1, 2015, QC Group’s training division separated from QC Group, LLC and began operation as a standalone business entity, QC Training Services, Inc.

They provide individual and group training in a variety of quality and manufacturing topics. If you are interested in these services, please contact them at qctraininginc.com.

Inquiries that we receive for training services will be forwarded.