3D Scanning Speeds Design Process in Aerospace and Defense.

The QC Group to Demo 3D Scanning Technology at MD&M Minneapolis.

September 30, 2015

Contract Dimensional Inspection and Capacity Additions for fast turnaround in Albuquerque, New Mexico.

October 20, 20153D Scanning Speeds Design Process in Aerospace and Defense.

We’re excited to have guest author Scott Shuppert provide his insight into the importance of both time and accuracy when scanning parts for the aerospace and defense industries. Scott is a 30-year veteran of the scanning industry and the owner of CAD/CAM Services, a full service CAD conversion company.

By Scott Shuppert

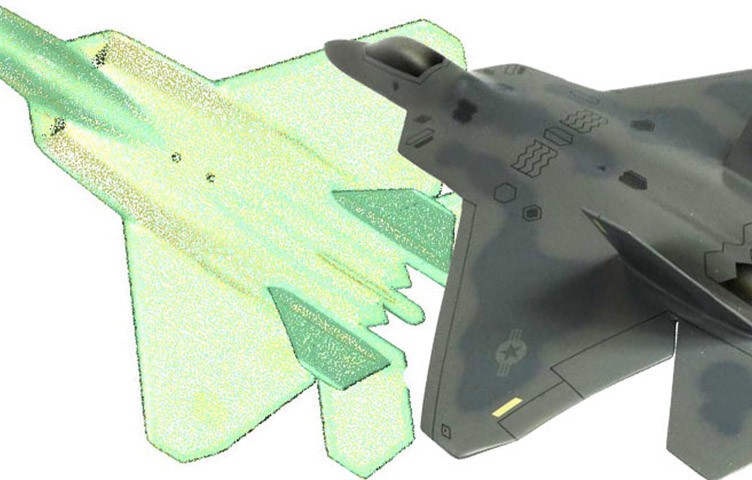

Accuracy and speed don’t always go hand in hand, yet often, in Aerospace and Defense, both are required. When the challenge is to reverse engineer a complex part and produce an accurate CAD model, the right 3D scanning technology can provide both speed and precision.

Traditional measurement methods are simply too labor intensive. Typically, in traditional methods, multiple iterations are required during the modeling process, in order to ensure that there are no missing or inaccurate measurements from the original parts.

But, by using a 3D laser scanner and software, reverse engineering can be done in a fraction of the time that traditional methods would take. Because the aerospace industry requires precision parts and components, 3D scanning is an ideal technology for use in building and maintaining aircraft.

It doesn’t matter where the part is located or how complex it is, 3D scanning works for everything from designing airframe parts and jet engine components to modeling aircraft bodies, and cockpit areas. Non-contact laser scanners capture millions of data points enabling even complex parts like turbines to be measured and modeled.

In an industry where minimizing downtime is critical, the speed with which 3D laser scanning can capture the data, and CAD programs can manipulate it, serves to reduce material waste and human error while maintaining aerospace production schedules and meeting defense deadlines.

Ensuring Access to the Right 3D Laser Scanner

Given the accuracy required for Aerospace applications, it’s imperative to use sophisticated and highly accurate scanners for precision reverse engineering. Things to consider when choosing a 3D scanner to for this application include:

- Accuracy and resolution

- Method and range of operation

- Color capture ability

- Portability

- Price

Particular attention should be paid to the accuracy, resolution and range requirements needed for precision reverse engineering.

Outsourcing

Given the precision and speed requirements of Aerospace applications, many Aerospace companies find that outsourcing with an established high-accuracy 3D scanning service enables them to focus on their core requirements, while the 3D model is being created for them. In terms of efficiency and cost, this can be far more productive than purchasing a scanner for in-house use. Companies who specialize in 3D scanning services have many different types of 3D scanners and are knowledgeable about which one will provide the best result for the object that needs to be scanned.

QC Engineering has extensive experience scanning and modeling aircraft replacement parts. Multiple pieces are scanned to develop a golden CAD model per your specs. Dimensional inspection results are recorded per AS9102 or per customer specifications for your FAA submittal requirements. Your project will be personalized – managed by a highly skilled individual with whom you will have a direct line of communication. Contact us today.