3D Scanning for Prosthesis.

Photo Credit Artec3D

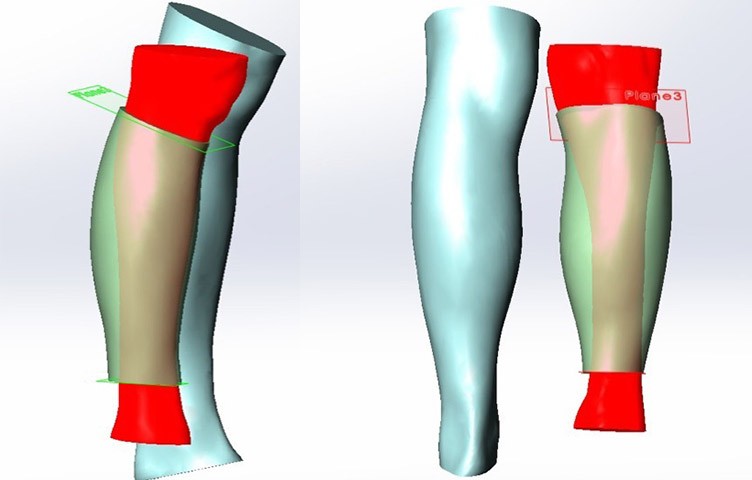

Medical manufacturing has come a long way with the advancement of new technology and materials. The fastest growing sectors are arguably orthopedics, reconstructive devices, hip implants, knee replacements, arthroscopy, and spinal implants. The traditional way to manufacture natural looking and customized prosthetic body parts involved castings out of plaster and then developing a computer-aided design (CAD) model. With the emergence of non-contact 3D scanning, the whole prosthetic device manufacturing process takes considerably less time with much faster data collection and improved accuracy. 3D imaging technologies combined with 3D printing (additive manufacturing) allows reduced design and development time and are now commonly used for surgical guides (such as conjoined twins separation) and prosthetics.

The Challenge.

Since the human body has mostly irregular shapes, traditional prosthetic manufacturing methods have often resulted in improper fitting, patient discomfort, and limited functionality. Customizing a fitted prosthetic device that evenly distributes pressure is one of the greatest challenges. Now, with highly accurate 3D models of the body, manufacturers are easily able to make custom prosthetic devices that are perfectly fitting and comfortable for patients.

According to Dr. Phil Reeves, Econolyst, United Kingdom “…the emergence of ‘digital healthcare’, where patients are benefiting from new automated scanning and diagnostic processes such as CT, MRI, 3D Ultrasound and intraoral laser scanning is providing the blue-print for future 3D printed healthcare solutions…”

More Accuracy. Better Design.

3D CT or MRI scanning was originally developed for the medical field and for years, surgeons and doctors have utilized these technologies, however, the scanned data was only presented and analyzed in 2D. With 3D printing (or additive manufacturing) the 3D scanned information can be converted into a highly accurate 3D model by systematically building it layer by layer from the ground up. Utilizing this technology, the 3D models can be used for diagnostic, pre-surgical aids and patient engagement purposes. The result is greater effectiveness and efficiency for clinicians, researchers, and hospitals, as well as improved outcomes for patients.

Rapid Production.

In the past, many attempts were made to build a model in CAD of an implant, but due to complex surfaces, these attempts proved difficult and frustrating, resulting in several unsuccessful rapid prototype iterations. Furthermore, it was difficult to reproduce medical devices without an existing CAD model.

Periodically, artificial medical devices need to be checked to detect wear and whether or not they need to be repaired or replaced accordingly. 3D scanning can solve all these problems by efficiently and quickly producing new matching parts by reverse engineering and computer aided verification.

QC Group Can Help.

QC Engineering’s focus and priority is to provide high quality advanced 3D scanning, modeling analysis, and geometry re-creation services that saves time and is cost effective for medical manufacturers. Our highly trained professionals can promptly scan and verify medical devices and components during the course of the development of your product.

Scanning applications include mating component analysis, surface area analysis, and full CAD model development. Our proficiencies are structured to personally assist you from precision device development into full production. We will personalize your project to accurately and precisely suit your needs. We pride ourselves on our quality service and there is no doubt that your manufacturing process will greatly benefit by more rapid and cost effective production results.

Behind the scenes, The QC Group has developed a rapid-response system that will transform expectations for speed of response and quote turnaround. Online requests for quotes are responded to within 5 minutes of submission, quotes in hand within 2 hours. Request yours at qcgroup.com/rfq.