Inspection of

Industrial

Equipment.

Rapid Response for Production Schedules.

When dimensional inspection is required on a key component of your industrial equipment, QC Group inspectors are available to turn the job quickly. Perhaps a cam profile is required to make a replacement or a shaft needs to be digitized. Rapid, accurate results are produced when your internal inspection simply cannot meet the demand and your equipment needs to be up and running. With tremendous capacity, our multiple lab locations can expedite an inspection and return the part to you quickly. Your project will be personalized - managed by a highly trained individual with whom you will have a direct line of communication.

Inspection of

Industrial

Equipment.

Rapid Response for Production Schedules.

When dimensional inspection is required on a key component of your industrial equipment, QC Group inspectors are available to turn the job quickly. Perhaps a cam profile is required to make a replacement or a shaft needs to be digitized. Rapid, accurate results are produced when your internal inspection simply cannot meet the demand and your equipment needs to be up and running. With tremendous capacity, our multiple lab locations can expedite an inspection and return the part to you quickly. Your project will be personalized - managed by a highly trained individual with whom you will have a direct line of communication.

Tell us about your project! Call 952-895-1150. 8am-5pm CST

- Story-Worthy Service

- Equipment, Capabilities

- Accreditation, Certifications

- Sample Reports

- Scanning for Inspection

Story-Worthy Dimensional Inspection Service

Built for responsiveness.

Our labs strive to provide services worth telling others about. We've structured our entire operation to be responsive to your needs – from precision equipment to be used on your type of parts, to IT systems built for optimum communications; we strive in every way to provide story-worthy service.

To take you to the next step.

When you begin a project with QC Inspection, we'll want to know your stated and unstated project needs. We value making and keeping aggressive commitments to help you get to the next step in your project. With a vast set of resources in multiple locations, there is always a way to get your measurement job done.

Lab Equipment, Capabilities.

Coordinate Measuring Machines (CMM)

- Brown & Sharpe CMMs with Continuous Scan (PC-DMIS)

- Zeiss Contura with Continuous Scan (Calypso)

- OGP Vision CMMs (Measuremind)

- Optiv Performance with Chromatic White Light Interferometry Scanning

- Optiv Classic (PC-DMIS)

- FARO/LDI Portable CMMs with Laser Scanners

Scanning Capabilities

- LDI Surveyor 3D Laser Scanners

- Cyberscan Confocal Micro-Scanners

- Chromatic White Light Interferometry Scanning

- Full-Contact Continuous CMM Scanning

Surface Finish Evaluation

- Zeiss Surfcom Profilometers

- CyberScan Laser Micro-Scanner (non-contact surface finish)

Support Capabilities

- Optical Comparators and other standard dimensional inspection equipment

- Robust Inventory Control System

- 2,000 lb hoist capacity

- Polishing Wheel

- Cutoff Machine

- Horizontal Bandsaw

- Parts Cleaning Station

For specific inquiries about equipment, software platforms and scanning capability, send us a message or call 952-895-1150.

Qualifications, Accreditations, and Certifications.

A2LA Accredited to ISO/IEC 17025:2005

ISO/IEC 17025:2005 specifies the general requirements for the competence to carry out tests and/or calibrations, including sampling. It covers testing and calibration performed using standard methods, non-standard methods, and laboratory-developed methods. - ISO.org

ASQ Certifications

All inspectors are certified to one or more of the following:

- CQI (Certified Quality Inspector)

- CMI (Certified Mechanical Inspector)

- CQT (Certified Quality Technician)

- CQE (Certified Quality Engineer)

- CQM (Certified Quality Manager)

- CQA (Certified Quality Auditor)

- A2LA Testing Cert: 1172.01

- Duns Number:19-993-4829

- NAICS: 541380 (Mech. Testing Lab or Services)

- Cage Code: 0GB04

- SIC Code: 8734

Something missing? Send us a message or call 952-895-1150 with special considerations.

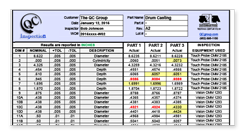

Sample Reports, Deliverables

Bubbled Print

Download the PDF 1.12 MBFirst Article Inspection Report (FAI)

Download the PDF 43.37 KBCertificate of Inspection

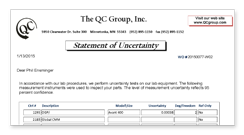

Download the PDF 60.86 KBStatement of Uncertainty

Download the PDF 51.98 KBDo you have special delivery requirements? We routinely customize our reports and data delivery based on customer need. Send us a message or call 952-895-1150 with special considerations.

When to use 3D precision scanning for your project.

Are you replacing a damaged component?

A 3D scan is helpful to capture the full geometry of damaged components. Then the original shape can be re-created by ‘knitting’ the geometry together in CAD or be using related features on the damaged part - such as another gear tooth.

Are you making a comparison of one part to another?

Performing a part-to-part comparison can be a daunting task if the results are presented in as a list of print features. A 3D comparative analysis can highlight trouble spots quickly. Perhaps then you will need more detailed information with a dimensional inspection of a localized area.

Is your part primarily controlled by profile with a few critical dimensions?

Industries continue to define more of a product’s features with profile tolerances. A 3D scan is the most descriptive method for reporting a profile and the variations throughout the surface. Your project may require that specific numerical profile data must be collected with a CMM. That same data can be reported from a scan output.

A Hybrid Solution

In these situations, we may recommend a hybrid inspection solution for your project that utilizes the 3D scanning and processing capabilities of QC Engineering, or combines these capabilities with traditional inspection techniques to provide the most useful data possible.

Get More Information on 3D ScanningSend us a message, or call us 952-895-1150, and let us guide you to the right solution.

Story-Worthy Dimensional Inspection Service

Built for responsiveness.

Our labs strive to provide services worth telling others about. We've structured our entire operation to be responsive to your needs – from precision equipment to be used on your type of parts, to IT systems built for optimum communications; we strive in every way to provide story-worthy service.

To take you to the next step.

When you begin a project with QC Inspection, we'll want to know your stated and unstated project needs. We value making and keeping aggressive commitments to help you get to the next step in your project. With a vast set of resources in multiple locations, there is always a way to get your measurement job done.

Lab Equipment, Capabilities.

Coordinate Measuring Machines (CMM)

- Brown & Sharpe CMMs with Continuous Scan (PC-DMIS)

- Zeiss Contura with Continuous Scan (Calypso)

- OGP Vision CMMs (Measuremind)

- Optiv Performance with Chromatic White Light Interferometry Scanning

- Optiv Classic (PC-DMIS)

- FARO/LDI Portable CMMs with Laser Scanners

Scanning Capabilities

- LDI Surveyor 3D Laser Scanners

- Cyberscan Confocal Micro-Scanners

- Chromatic White Light Interferometry Scanning

- Full-Contact Continuous CMM Scanning

Surface Finish Evaluation

- Zeiss Surfcom Profilometers

- CyberScan Laser Micro-Scanner (non-contact surface finish)

Support Capabilities

- Optical Comparators and other standard dimensional inspection equipment

- Robust Inventory Control System

- 2,000 lb hoist capacity

- Polishing Wheel

- Cutoff Machine

- Horizontal Bandsaw

- Parts Cleaning Station

For specific inquiries about equipment, software, platforms and capability, send us a message or call 952-895-1150.

Qualifications, Accreditations, and Certifications.

A2LA Accredited to ISO/IEC 17025:2005

ISO/IEC 17025:2005 specifies the general requirements for the competence to carry out tests and/or calibrations, including sampling. It covers testing and calibration performed using standard methods, non-standard methods, and laboratory-developed methods. - ISO.org

ASQ Certifications

All inspectors are certified to one or more of the following:

- CQI (Certified Quality Inspector)

- CMI (Certified Mechanical Inspector)

- CQT (Certified Quality Technician)

- CQE (Certified Quality Engineer)

- CQM (Certified Quality Manager)

- CQA (Certified Quality Auditor)

- A2LA Testing Cert: 1172.01

- Duns Number:19-993-4829

- NAICS: 541380 (Mech. Testing Lab or Services)

- Cage Code: 0GB04

- SIC Code: 8734

Sample Reports, Deliverables

Bubbled Print

Download the PDF 1.12 MBFirst Article Inspection Report (FAI)

Download the PDF 43.37 KBCertificate of Inspection

Download the PDF 60.86 KBStatement of Uncertainty

Download the PDF 51.98 KBDo you have special delivery requirements? We routinely customize our reports and data delivery based on customer need. Send us a message or call 952-895-1150 with special considerations.

Tell us about your project! Call 952-895-1150. 8am-5pm CST

"In a hyper-focused myopic state I had the models to be scanned shipped out to your people before confirming the schedule. Your team could have justifiable said 'your timing problem is not our problem!'

Instead, in seamless fashion, first contact with Steve led me to a quote from Julie and Ryan is getting us what we need. We got client approval Tuesday afternoon, shipped the models to you, and our first scans were in hand by Thursday afternoon.

Excellent team work."

- Jonathan T, bleck design group